Shoe prototypes

JULIE BLANCHARD

CLAY

STYROFOAM

PAPER CUPS

Stool models

Straw model

Artist research

Ceramic molding

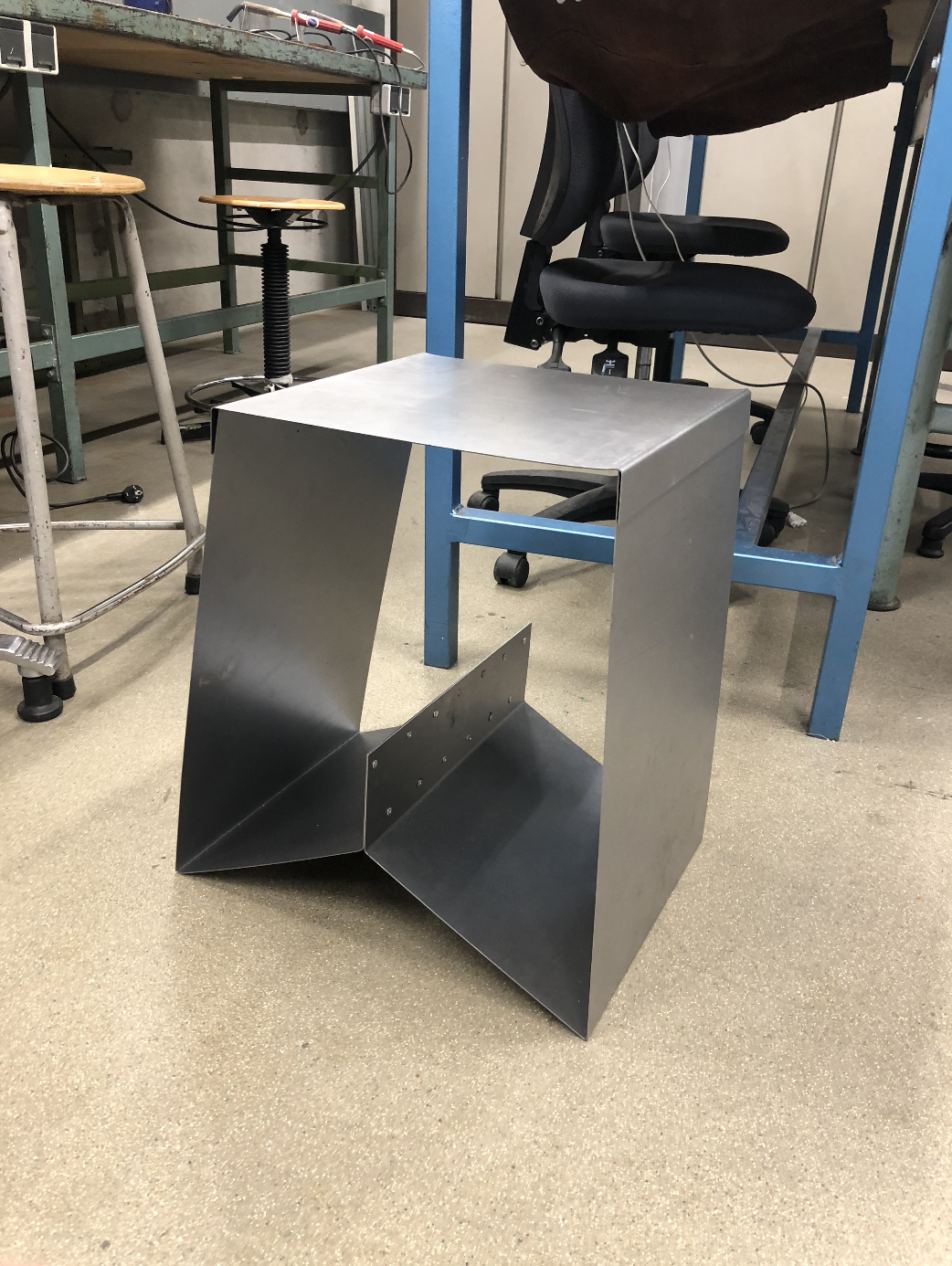

I decided the smartest idea would be to divide the 1m2 metal sheet into three equal sections of 33.3cm in length.

Two of those sheets will be used to create the sides of the chair and the third one will be used for the top and the supporting middle piece of the stool.

I calculated the lengths and angles I want to cut and bend the sheets in to achieve the most seamless result I possibly can for my final prototype.

Step 1: I bent the two big slices for the sides in a 120 degree and then 75 degree angle to form the wanted shape.

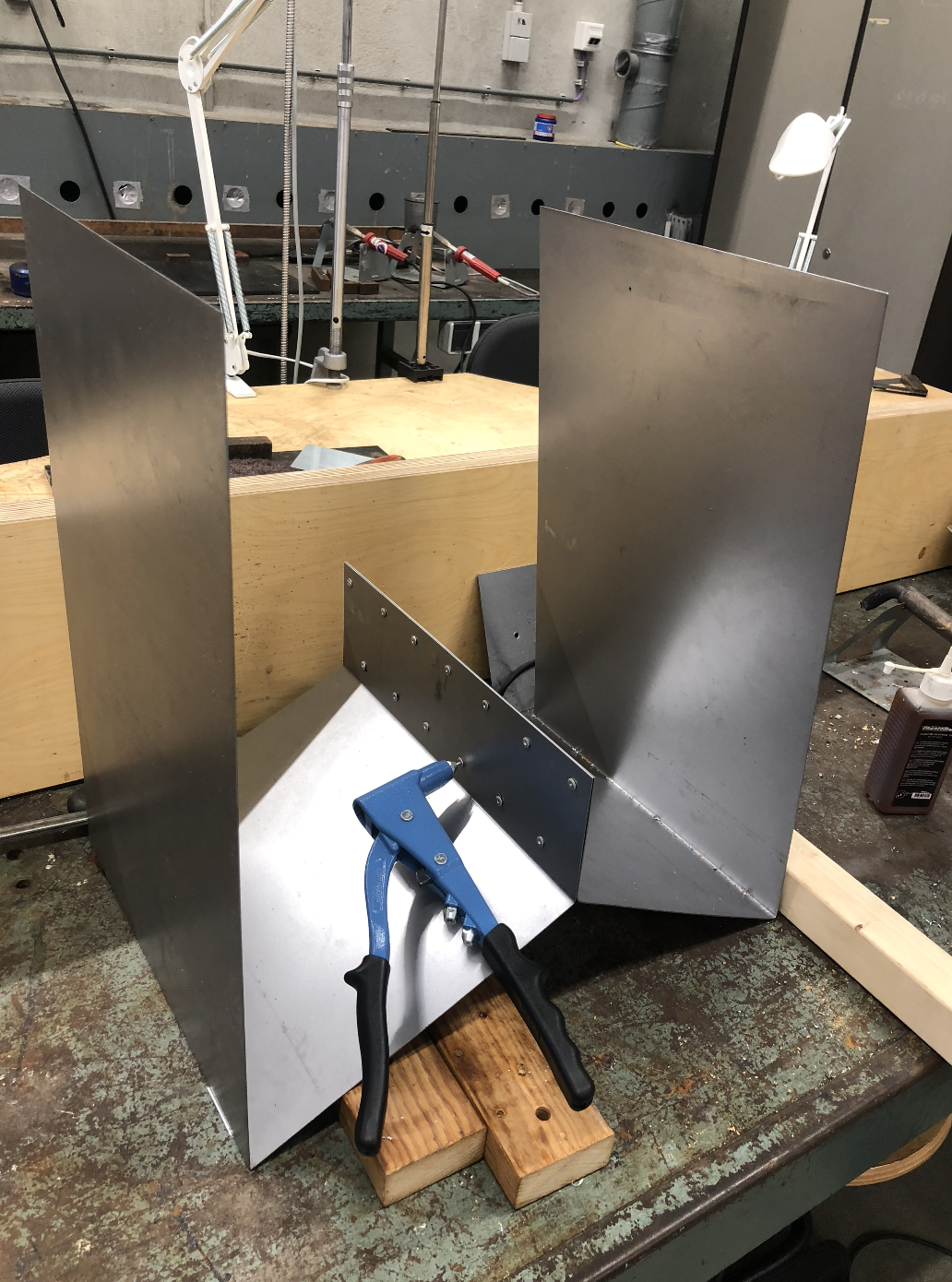

Step 2: I used the excess piece from the metal sheet as a template and measured the distances between the points where i want to connect the two metal sheets. I decided to go for a zig zag pattern which adds to the aesthetic of the chair.

Step 3: I first hammered points onto the template which I then drilled and smoothed out.

Step 4: I put the template onto the part of the metal sheets where I want them to be attached and secured it together. From that, I just drilled into the two metal pieces and smoothed out the edges as much as I could.

Step 5: I then attached rivets that connect the two pieces of metal together to make it stable.

Wooden box

HOME

HOMEPAGE